IFEFLUX series identifies a range of filters that are particularly suitable for industrial water and sea water filtration.

When mussels, fish, grass and foliage affect the functionality of your plants, you can find the solution in installing multi-camera filters.

Operation:

The operation of IFEFLUX series filters is very simple extremely effective.

The entire equipment is designed for 24 hours operation and in unmanaged areas.

All the phases of the operation can be displayed on control panel and / or remote control.

The filter initially works as a regular static filter (the rotating arms are stopped and the drain valve is closed).

The flow of water crosses the filtering multi-chambers which hold all the impurities with granulometric equal to the filtration degree chosen.

Note that thanks to the large filter surface the differential pressure on the filter elements rises very slowly (figure 1).

When the differential pressure reaches the maximum value (set by the user), the backwashing phase automatically start, regenerating the filter elements.

Even at this stage, the exercise is guaranteed and the flow is not interrupted.

An internal rotating arm ensures the cleaning of the whole filter surface while washing water comes discharged with all the impurities collected by the drain valve.

The entire cleaning cycle works from 60 to 120 seconds

(settable directly from the system).

Special features and benefits:

– Accurate execution which ensure at all points a seal equal to the selected filtration degree.

– Short washing time wich ensure less water discharge.

– High filtering surfaces.

– High accumulation capacity.

– Low pressure drop.

– High security and efficiency.

– No external fluid required for washing.

– Reduced size.

– Cleaning is guaranteed even with low operating pressures.

– Possibility of installation both vertically and horizontally.

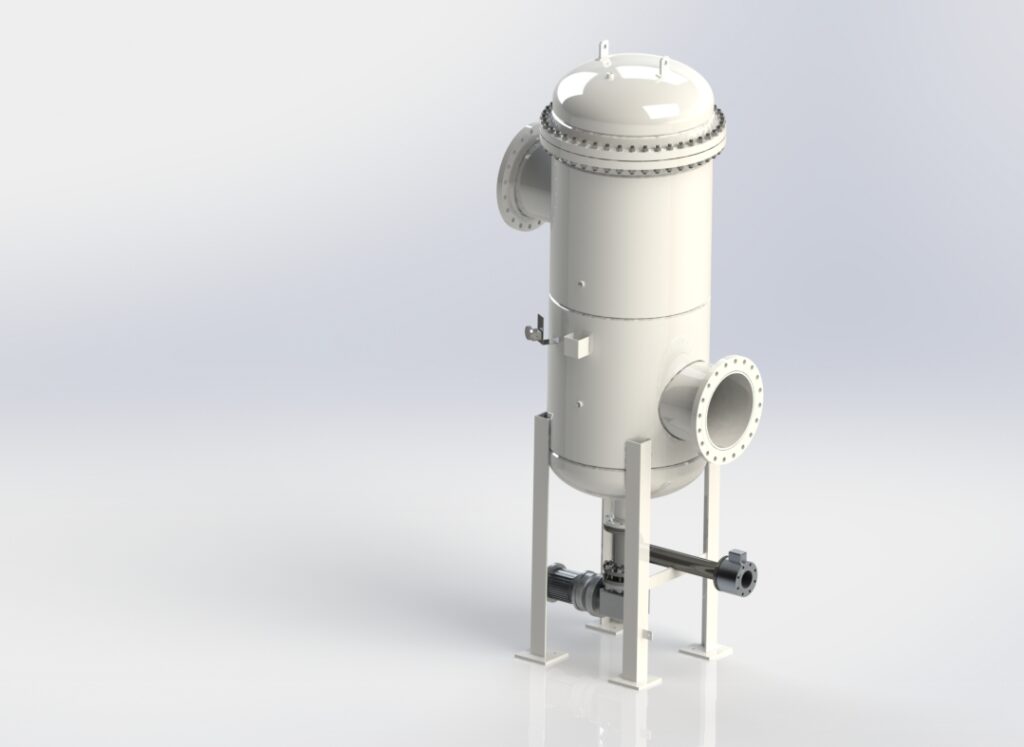

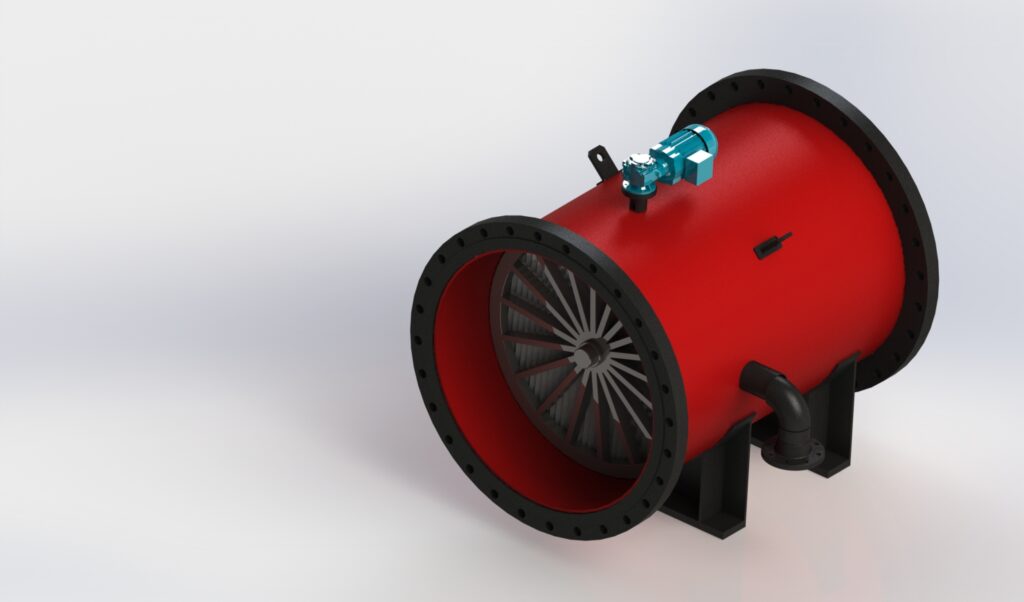

IFEFLUX Automatic Filters can be supplied in two different versions (both for vertical and horizontal mounting)

IFEFLUX/AT:

Multi-chamber with filter tubes

IFEFLUX/AD:

Multi-chamber with disc

The particular shape of the wire allows an efficient filtration and easy release of impurities during backwashing.

Main components:

– A welded body with IN / OUT flanged.

– Multi-chamber candles or disc filtering elements.

– Gear-motor for rotating of the internal washing arm.

– Actuated valve for the drainage of the fluid.

– Differential pressure switch.

– Control panel.

Technical data:

IFEFLUX / AT

DN (inches) 2 “÷ 30”

Filtering Degree (mm) 0.05 ÷ 2

Minimum operating pressure required (bar) 2.5

Pressure rating (bar) 6 ÷ 64

IFEFLUX / AD type filter

DN (inches) 24 “÷ 114”

Filtering Degree (mm) 1 to 8

Minimum operating pressure required (bar) 0,5

Pressure rating (bar) \ 6 ÷ 16

Filters can be made of different materials and protections that will be defined in agreement with the customer’s requirements.